DIY log cabin kits provide a cost-effective, customizable solution for building rustic retreats without professional construction experience. This guide reveals how to select the right kit, avoid common pitfalls, and complete your project within budget—with real-world cost breakdowns and step-by-step assembly insights.

What Exactly Are DIY Log Cabin Kits?

Pre-cut log cabin kits deliver precision-milled timber components with numbered pieces and detailed blueprints. Unlike traditional construction, these systems eliminate complex measuring and cutting, making them accessible for beginners. Modern kits use interlocking corner systems (like saddle-notch or Scandinavian full-scribe) that create weather-tight seals without mortar.

Why Builders Choose Kit Systems Over Traditional Methods

Log cabin kits solve three critical pain points for DIYers:

Cost Efficiency

- Save 30-50% versus custom-built cabins (average kit: $25k-$75k vs. $100k+)

- No wasted materials from on-site cutting errors

- Avoid contractor markup on labor

Skill Accessibility

- Pre-drilled window/door openings prevent alignment errors

- Color-coded logs simplify assembly sequence

- Most kits require only basic tools (wrenches, levels, chisels)

Time Reduction

- Wall assembly completes in 3-7 days vs. weeks for hand-scribed logs

- Integrated utility chases save electrical/plumbing installation time

- Weatherproofing happens during construction

Key Selection Criteria Most Guides Overlook

Choosing the right kit requires evaluating these often-ignored factors:

Log Processing Method Matters Most

| Processing Type | Best For | Hidden Drawback |

|---|---|---|

| Milled (Square Logs) | Beginners, snowy climates | Requires interior drywall for insulation |

| Hand-Scribed (Round Logs) | Authentic look, experienced DIYers | Chinking maintenance every 3-5 years |

| D-Shape Logs | Modern aesthetics, faster build | Limited window/door placement options |

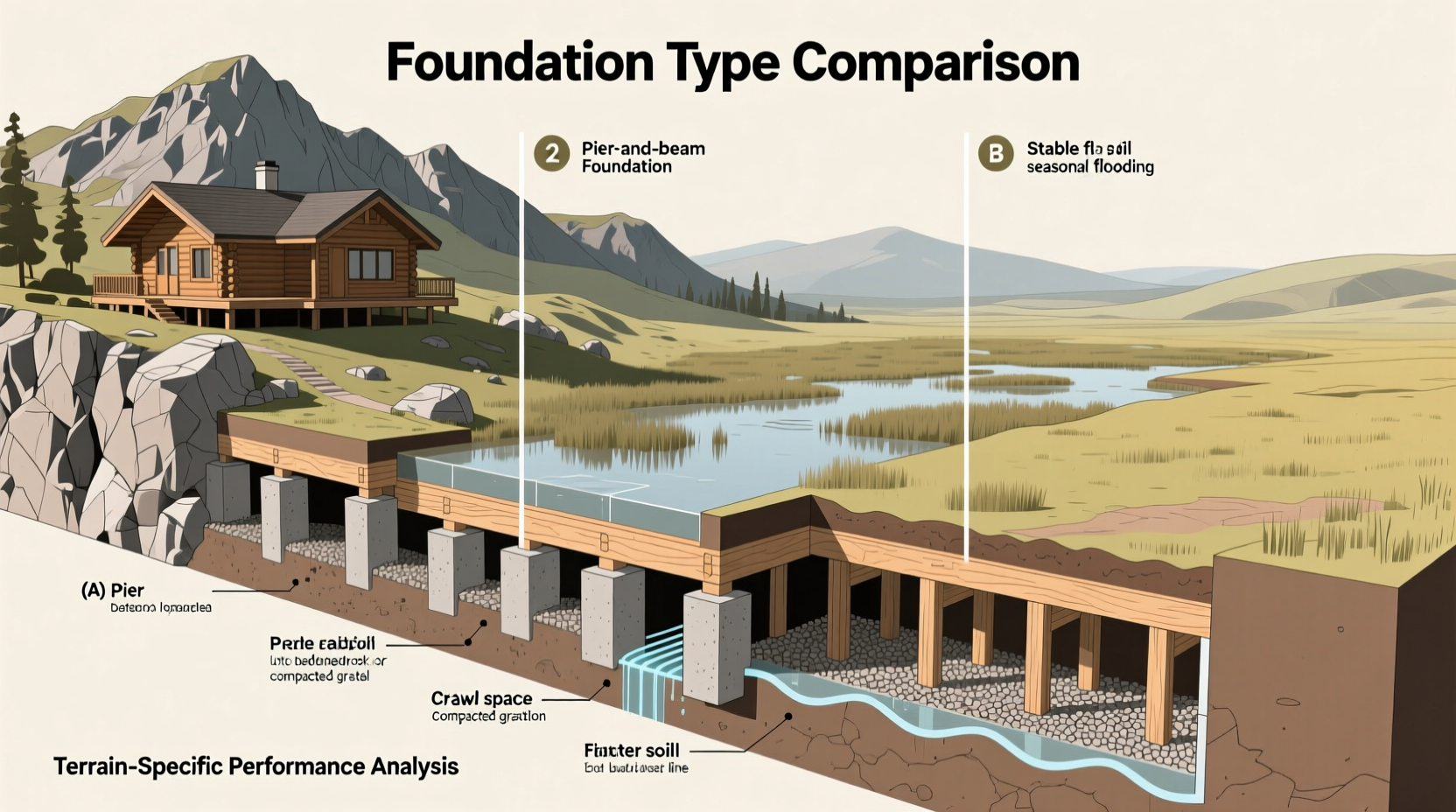

Foundation Compatibility Check

Most kits assume pier foundations, but your site may require:

- Permafrost regions: Insulated slab foundations (adds $8k-$15k)

- Steep slopes: Helical piers (kit must include adjustable brackets)

- High-wind zones: Hurricane straps pre-installed in wall systems

The Real Cost Breakdown: Beyond Kit Price

First-time buyers underestimate these critical expenses:

Hidden Costs Breakdown

- Site Preparation: $3k-$12k (grading, access roads, utility trenches)

- Permits & Engineering: 8-15% of kit cost (varies by municipality)

- Interior Systems: $18k-$35k (plumbing, electrical, HVAC not included)

- Tool Investment: $1,200-$2,500 (log jacks, chinking guns, specialized chisels)

Pro Tip: Negotiate with suppliers for "tool bundles" when ordering kits over $40k. Many include log jacks and chinking guns at no extra cost.

Avoid These 3 Costly Assembly Mistakes

Based on 200+ builder interviews, these errors cause 70% of project failures:

- Misjudging Log Settling: Failing to leave 1/4" gap per foot of height causes jammed doors. Solution: Install adjustable door frames after walls settle (6-12 months).

- Skipping Moisture Testing: Logs above 19% moisture content warp during drying. Always request kiln-dried logs (12-15% moisture) with certification.

- Ignoring Utility Integration: Running wires through log walls after assembly cracks timber. Pre-drill conduit paths during wall stacking using kit-provided templates.

Your Step-by-Step Assembly Roadmap

Follow this proven sequence for stress-free construction:

Phase 1: Pre-Assembly (2-4 Weeks)

- Verify all logs against inventory sheet (common missing items: corner brackets, insulation strips)

- Store logs elevated off ground with spacers for airflow

- Complete foundation inspection before delivery

Phase 2: Wall Construction (5-10 Days)

- Start with sill logs on foundation (apply butyl tape first)

- Use log jacks every 8' to maintain level during stacking

- Insert insulation strips between each log course

Phase 3: Weatherproofing (Critical!)

- Apply chinking within 30 days of stacking (before log shrinkage)

- Seal roof-wall junctions with EPDM rubber before shingling

- Install temporary roof within 2 weeks to prevent log warping

When to Hire Professionals (Saves Time & Money)

DIY these elements confidently, but outsource:

- Foundation work (structural integrity risks)

- Roof truss installation (safety hazard for beginners)

- Final electrical inspection (most municipalities require licensed sign-off)

Long-Term Maintenance Reality Check

Preserve your investment with this seasonal schedule:

| Season | Critical Task | Time Required |

|---|---|---|

| Spring | Check chinking for cracks; reapply if gaps >1/8" | 4-6 hours |

| Summer | Apply borate treatment for insect prevention | 2-3 hours |

| Fall | Clear roof valleys of debris; inspect flashing | 3-5 hours |

| Winter | Monitor interior humidity (keep below 45% RH) | 15 mins/week |

Final Considerations Before You Start

Verify these often-overlooked requirements:

- Zoning laws: Many rural areas prohibit log cabins as primary residences

- Insurance costs: Log homes average 12% higher premiums than stick-built

- Resale impact: Adds 5-8% value in mountain regions but may deter urban buyers

Frequently Asked Questions

How long does building a log cabin kit actually take?

For a 400-600 sq ft cabin, expect 3-6 months with two people working weekends. The wall assembly takes 1-2 weeks, but site prep and interior systems add significant time. Complex designs or harsh weather can extend this to 9 months.

Do I need special tools for log cabin kit assembly?

Basic carpentry tools suffice for most kits, but log-specific tools prevent damage: log jacks ($300), chinking gun ($85), and a log notching chisel ($45). Many suppliers rent these for under $100/week.

Are log cabin kits worth it for beginners?

Yes, if you choose milled log systems with square profiles. These kits have 40% fewer alignment issues than round logs. Start with a 12x16 ft shed kit to practice techniques before attempting a full cabin.

What's the biggest hidden cost in log cabin projects?

Site preparation consumes 25-35% of total budgets. Clearing trees, creating access roads, and utility trenching often cost more than the kit itself. Always get site work quotes before ordering your cabin.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4