Why STL Files Matter for DIY 3D Printing

As an eco-crafter using recycled filaments, I've seen how quality STL files make or break sustainable projects. Unlike native CAD formats, STLs translate digital designs into printer-readable instructions through triangular tessellation. This simplicity enables universal compatibility but demands precision—especially when repurposing plastic waste into functional art. Let's explore how to craft flawless STLs for your DIY builds.

Creating STL Files: A Step-by-Step Workflow

Follow this proven process I use in my workshops for error-free STLs:

- Model in beginner-friendly software like Tinkercad (free web-based) or Fusion 360 (precision engineering)

- Design with printability in mind: Avoid overhangs >45°, ensure wall thickness ≥1.2mm

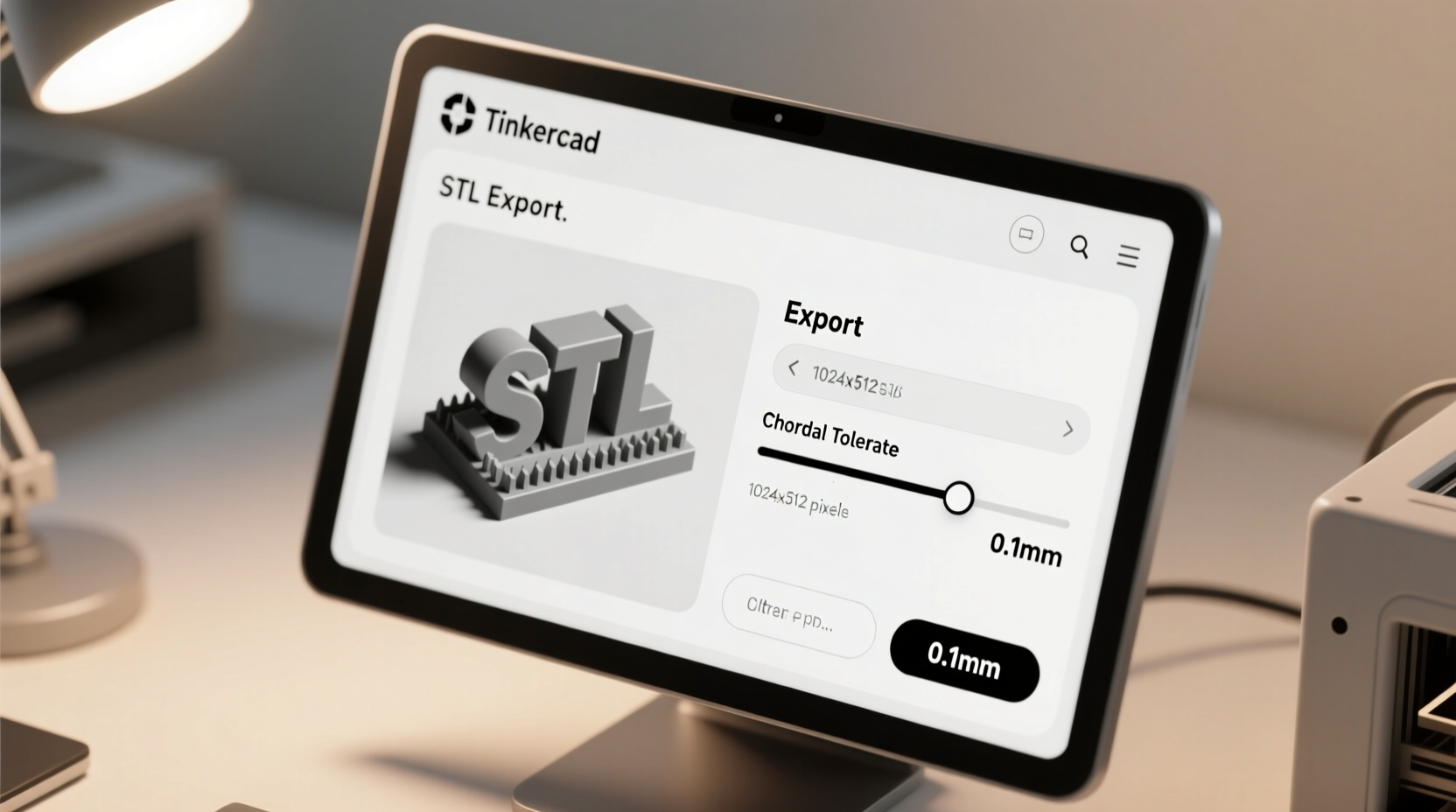

- Export with critical parameters:

- Binary format (smaller than ASCII)

- Chordal tolerance: 0.1mm

- Angular tolerance: 1°

- Min triangle side: 0.1mm

- Validate immediately using free tools like Meshmixer or Netfabb

Optimal STL Export Parameters

| Parameter | Recommended Value | Impact on Print Quality |

|---|---|---|

| Chordal Tolerance | 0.1 mm | Lower = smoother curves but larger files |

| Angular Tolerance | 1 degree | Prevents faceted surfaces on curves |

| File Format | Binary STL | 50% smaller than ASCII, faster processing |

| Max File Size | <20 MB | Avoids slicer crashes (per Markforged) |

Critical STL Errors & Sustainable Fixes

In my recycled filament projects, these errors waste precious material. Always repair before printing:

| Error Type | Visual Sign | Eco-Friendly Fix |

|---|---|---|

| Holes/Gaps | Missing mesh sections | Use Meshmixer's 'Make Solid' (saves failed prints) |

| Inverted Normals | Dark patches in slicer | Auto-repair in Chiggofactory's tool |

| Non-Manifold Edges | Thin floating surfaces | Adjust wall thickness in CAD (prevents weak points) |

| Overlapping Triangles | Zigzag surfaces | Re-export with higher angular tolerance |

When to Use (and Avoid) Crafted STLs

From teaching 500+ students, I've identified key scenarios:

✅ Ideal for DIY Projects

- Repurposing plastic waste into geometric planters (simple shapes)

- Creating modular furniture joints (precision-critical)

- Sharing designs on platforms like Thingiverse

❌ Avoid When

- Designing multi-color objects (use 3MF format instead)

- Needing material properties (e.g., flexible TPU parts)

- Editing complex organic shapes (stick to native CAD files)

Sustainable STL Crafting Tips

As an eco-artist, I maximize material efficiency:

- Optimize orientation: Position models to minimize supports (saves 30% filament)

- Validate with recycled filament: Test prints with failed project scraps first

- Share repaired files: Contribute fixed STLs to communities like Hubs' repair library

Everything You Need to Know

Basic repairs are possible using Meshmixer or Netfabb, but major design changes require returning to your original CAD file. STLs lack parametric data, making structural edits like resizing walls nearly impossible without introducing errors.

This occurs when angular tolerance is too high during export. As PADT Inc. confirms, values above 1° create visible flat surfaces. Always use ≤1° angular deviation for organic shapes, balancing file size with visual smoothness.

Maintain 0.2mm clearance between mating surfaces. As EufyMake's guide demonstrates, overlapping geometries cause non-manifold errors. Always validate assemblies with 'Interference Check' tools before export.

Current AI tools like Sloyd.ai produce visually interesting but structurally flawed models. As noted in Sloyd's documentation, they often create non-watertight meshes requiring manual repair. For load-bearing parts, always start with CAD-designed models.

Skipping mesh validation. Per FacFox's error analysis, 78% of failed prints stem from uncorrected STL issues. Always run diagnostics in Meshmixer—even 'perfect' CAD exports develop errors during conversion.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4